Blade Tension-The direct pull (in pounds) on the blade.

Beam Strength-The resistance a saw blade has to back deflection when subjected to the edge thrust of feed pressure.

Camber- An arcing or bending of the back or cutting edge of the saw blade. In positive camber the cutting edge arcs backward; in negative camber the cutting edge arcs forward.

Carbon Steel-The result of carbon being added to iron in the making of the steel.

Chatter-Rumbling sound in the machine caused by trying to take too heavy a cut. The sound comes from overloading the machine.

Chip-A small fragment of material removed by each tooth on the cutting edge.

Chip Clearance- The gullet area between two teeth.

Cutting Rate- The speed at which the cross sectional area of the work piece is cut, expressed in square inches of cutting per minute.

E.T.S. (Every Tooth Set) - Each tooth is alternately set left then right, used generally in woodworking and for non-ferrous metals. Also know as alternate set. Spring steel blades only.

Feed-The pressure exerted by the work piece against the cutting edge of a saw blade expressed in pounds

Feed Rate- The linear travel of the work piece into the blade, usually expressed in inches per minute.

Flex Rate- Saw blade with hardened teeth but a relatively soft back.

Gullet- The space within the curved area between two saw blade teeth.

Hard Back- A type of high carbon, spring tempered back saw bladeOlson Hard Edge Flex Back Band Saw Blades.

Hook Tooth- A tooth form consisting of a shallow gullet and widely spaced teeth having a positive rake angle. Olson Hook Tooth Blade

Kerf- The slot made by a cutting tool in parting material.

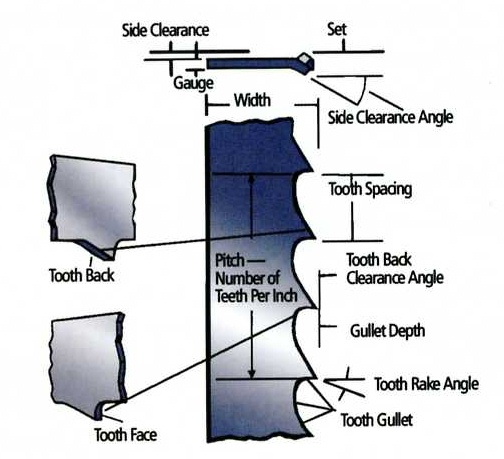

Pitch- The number of teeth per inch in a saw blade.

Points- The tips of teeth in a saw blade.

Rake Angle- The angle the tooth face makes with respect to a perpendicular line from the back edge of the blade. It is positive when the tooth angles forward in the direction of the cutting action and negative when it angles backward from the direction of the cutting action.

Raker Set- A saw tooth pattern in which one tooth is set right, the next to the left and the third is straight.

Regular Tooth (Conventional tooth) - A tooth form consisting of a deep gullet with a smooth radius at the bottom. Olson Regular Tooth Band Saw Blade

Set- The bending of teeth in a saw blade to the left and/or right of center. The setting of teeth enables a saw blade to cut straighter, to clear the chips from the kerf, and to allow the back of the band to clear the cut and not bind.

Side Clearance- The difference in dimension between the set of the teeth and the back of the blade. It provides space for maneuvering the band in contour cuts, prevents lead when making straight cuts and minimizes transfer of frictional heat to the work.

Skip Tooth-A tooth form consisting of a shallow gullet with widely spaced teeth to provide for ample clearance.0 degree rake angle. Olson Skip Tooth Band Saw Blade

Strippage-When one or more teeth are pulled or break out of a saw blade.

Twist- The tendency of a saw blade to spiral after use.

Wavy Set- A saw tooth pattern having one group of teeth set to the right and the next group set to the left to give the appearance of a wave viewed from the top of the blade.